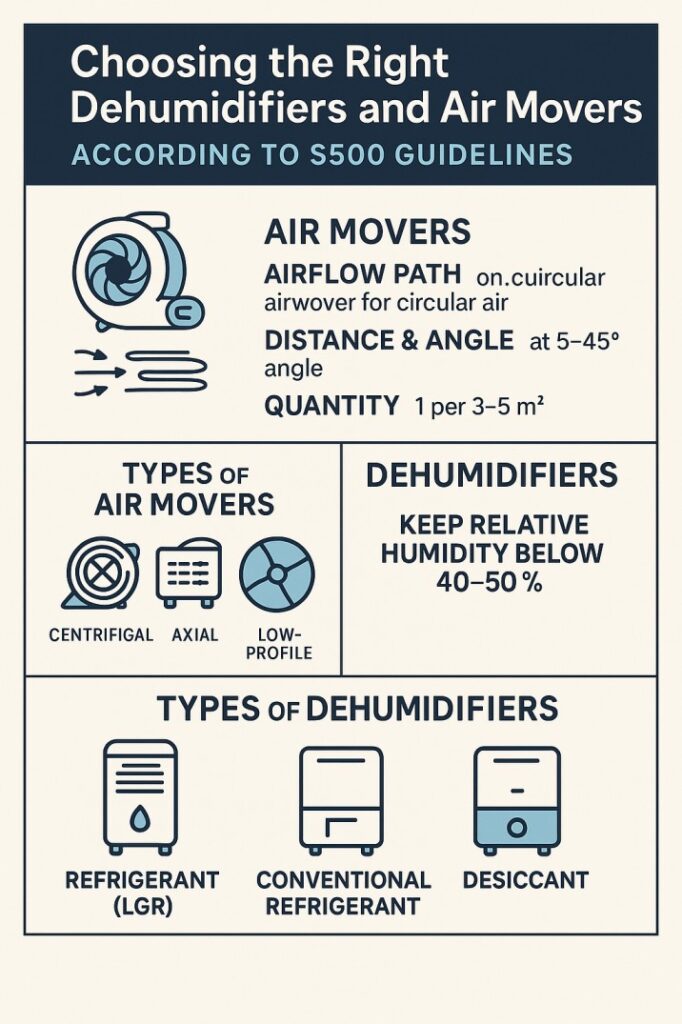

Choosing the Right Dehumidifiers and Air Movers According to S500 Guidelines

When water damage strikes, the success of the drying process depends on more than just turning on a few fans.

The ANSI/IICRC S500 Standard for Professional Water Damage Restoration provides a detailed framework for selecting and positioning dehumidifiers and air movers to ensure efficient drying and prevent secondary damage such as mould growth, odours, or structural decay.

This guide explains how professionals calculate equipment needs and why proper selection is critical for safe, standards-compliant restoration.

Why Equipment Choice Matters

Drying equipment must do two things simultaneously:

-

Accelerate evaporation from wet materials.

-

Remove moisture from the air to maintain a low humidity environment.

If either step is miscalculated—too little airflow or insufficient dehumidification—drying slows and mould growth can begin within 24–48 hours.

Step 1: Determine Water Class and Category

The S500 requires technicians to identify:

-

Category (1–3) – Level of contamination (clean, grey, or black water).

-

Class (1–4) – Extent of saturation and evaporation load.

This classification drives every decision about equipment quantity and type.

Step 2: Selecting Air Movers

Air movers create high-velocity airflow across wet surfaces, increasing the rate of evaporation.

Key Factors:

-

Airflow Path – Place units to create a circular airflow pattern for even drying.

-

Distance & Angle – Aim at a 15–45° angle to lift moisture from flooring and wall surfaces.

-

Quantity – S500 guidelines typically recommend:

-

1 air mover per 3–5 square metres of affected floor area, adjusted for Class 3 or 4 jobs.

-

Types of Air Movers:

| Type | Best Use |

|---|---|

| Centrifugal | Focused airflow for walls, corners, and cavities. |

| Axial | High-volume airflow for open areas and ceilings. |

| Low-Profile | Tight spaces, under cabinets, or beneath carpet edges. |

Step 3: Selecting Dehumidifiers

Dehumidifiers capture moisture released into the air by evaporation, keeping relative humidity (RH) below 40–50% to prevent mould.

Types of Dehumidifiers:

| Type | Ideal Conditions | Key Features |

|---|---|---|

| Refrigerant (LGR) | Warm, humid environments | Energy efficient, excellent for most Class 1–3 jobs. |

| Conventional Refrigerant | Mild temperatures | Cost-effective for small jobs. |

| Desiccant | Cool or specialty drying (Class 4) | Uses silica gel to pull moisture even in low temperatures. |

S500 Equipment Sizing

-

Calculate the room’s cubic metres to determine required pints of water removal per day.

-

For Class 3 or 4 jobs, add additional capacity or specialty units to handle high evaporation loads.

Step 4: Monitoring and Adjusting

Even with the right equipment, continuous monitoring is essential:

-

Daily checks of temperature, relative humidity, and moisture content.

-

Adjust placement or add units as readings approach S500 “dry standard” goals.

Reztor’s S500-Compliant Approach

At Reztor Restoration, our IICRC-certified technicians:

-

Perform a full psychrometric assessment using moisture meters and hygrometers.

-

Calculate the precise air mover count and dehumidifier capacity required for each class of water damage.

-

Use industry-leading equipment—commercial LGR dehumidifiers, HEPA air movers, and specialty inject-dry systems—for efficient, safe results.

Every job is documented with equipment logs and moisture readings, giving property owners and insurers clear evidence of standards-based drying.

Key Takeaways

-

Correct equipment selection is critical for fast, safe drying.

-

Air movers drive evaporation; dehumidifiers capture moisture.

-

The IICRC S500 provides calculations for quantity, type, and placement to ensure a successful restoration.

Need Expert Drying?

Don’t guess when it comes to drying equipment.

Call Reztor Restoration for S500-compliant water damage restoration and 24/7 emergency service.

Contact Us Today

1800 739 867